Key Takeaways

- Liquid manufacturing is evolving with advancements in technology and processes.

- Sustainability in manufacturing is becoming increasingly important.

- Consumers and businesses alike are benefitting from these innovations.

Table of Contents

- The Rise of Liquid Manufacturing

- Innovations in Technology

- Sustainable Practices

- Healthcare and Pharmaceuticals

- Food and Beverage Industry

- Cosmetics and Personal Care

- Challenges and Future Prospects

- Conclusion

The Rise of Liquid Manufacturing

In recent years, liquid manufacturing has seen significant growth and innovation, transforming how products are created across various industries. Utilizing high-precision technology, this method allows for the efficient and flexible production of everything from pharmaceuticals to cosmetics. But what exactly is driving this surge in liquid manufacturing?These partnerships help ensure high-quality outputs and meet rigorous industry standards, enabling businesses to scale efficiently.

Innovations in Technology

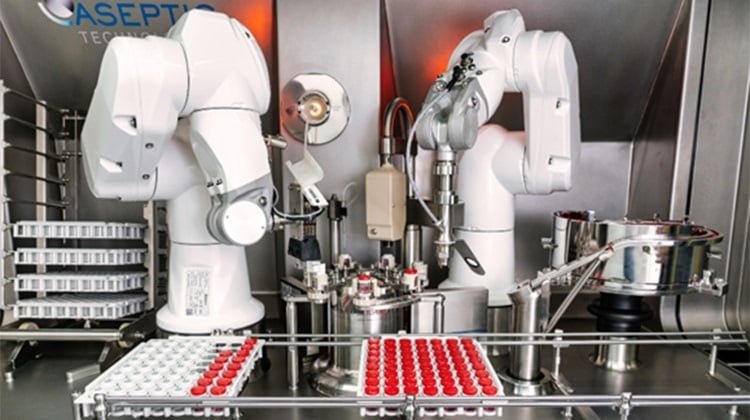

Advanced machinery and automation are revolutionizing modern liquid manufacturing processes. Finding a reliable supplement manufacturing partner has enhanced the production capabilities of many companies. Techniques such as microencapsulation allow for the precise inclusion of active ingredients, while high-shear mixing ensures uniform distribution throughout the product. These innovations lead to greater consistency and quality. According to recent articles, the technology behind liquid manufacturing is continually evolving to meet consumer demands for better and safer products. This constant innovation gives businesses the tools to stay competitive in a rapidly changing market.

Sustainable Practices

Sustainability is no longer just a buzzword; it’s a necessity for modern manufacturing. Liquid manufacturing processes have increasingly incorporated eco-friendly practices, significantly reducing waste and conserving valuable resources. Reputable sites like Green Manufacturing News provide comprehensive insights into how companies achieve sustainability goals. From using biodegradable materials in the packaging to implementing energy-efficient machinery, these sustainable practices offer substantial environmental benefits while also proving to be cost-effective in the long term. This double advantage makes sustainable practices a cornerstone of modern liquid manufacturing.

Healthcare and Pharmaceuticals

Liquid manufacturing plays a pivotal role in the healthcare and pharmaceutical industries. Its precision and customization capabilities allow the production of complex medications tailored to meet specific needs. Liquid formulations can be adapted for pediatric or geriatric patients requiring specific dosages, which is critical for personalized medicine. For example, specialized liquid compounds can target specific health conditions more effectively than traditional solid forms. This adaptability ensures patients receive optimal treatment while allowing healthcare providers to offer more diverse medication options.

Food and Beverage Industry

The food and beverage industry has also reaped the rewards of liquid manufacturing innovations. New methods of pasteurization and bottling have extended shelf life and improved safety standards. This benefits consumers by ensuring product quality and safety and significantly reduces waste across the supply chain. In an industry heavily scrutinized for food safety and waste, these advancements boost efficiency and reliability. For example, aseptic packaging techniques have allowed beverages to remain fresh without preservatives, meeting consumer demands for natural products.

Cosmetics and Personal Care

Liquid formulations are often favored for their versatility and ease of application in beauty and personal care. Creating tailored products such as specific skin serums, shampoos, and conditioners is a significant advantage in a market that values personalization. Consumers increasingly seek products that cater to their unique needs, from anti-aging solutions to specialized hair treatments. Liquid manufacturing allows brands to innovate continually, offering new and exciting products that meet these evolving consumer preferences, ultimately driving brand loyalty and market growth.

Challenges and Future Prospects

While the advancements in liquid manufacturing are commendable, they come with challenges. Quality control and regulatory compliance remain critical issues that manufacturers must navigate to ensure product safety and efficacy. Constantly changing regulations and the need for rigorous testing can be daunting, but these challenges also drive continuous improvement in the industry. Constant innovation and adherence to best practices will be crucial for maintaining growth and consumer trust. Companies that can adapt to these challenges while capitalizing on new opportunities are poised for long-term success in the evolving landscape of liquid manufacturing.

Conclusion

Liquid manufacturing is a transformative force across various industries, improving health outcomes and enhancing daily lives. As technology progresses and sustainable practices become the norm, the future of liquid manufacturing looks bright and promising. Businesses that embrace these advancements and invest in quality partnerships will likely thrive, benefiting consumers and the environment. The evolution of liquid manufacturing is about keeping up with trends and setting new standards for quality, sustainability, and innovation.